We are professional Fried Corn Nuts production line manufacturer in Taiwan.We supply best quality and best running condition equipment for customers in the world.

We provide the production capacity from 100 KG per hour to 2000 KG per hour.

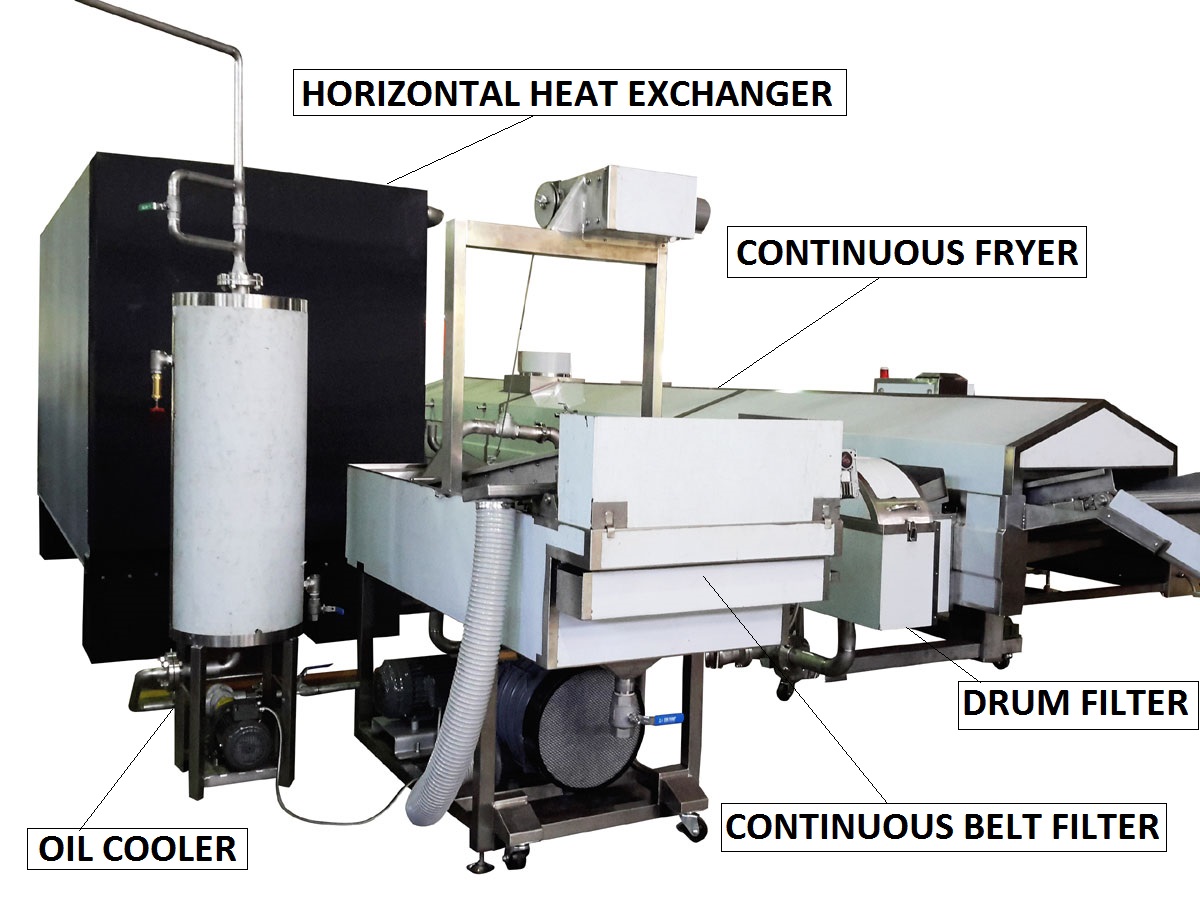

Model WJFCN-001 Fried Corn Nuts Production Line included

Soaking System

1. Corn Discharge conveyor

2.. Corn cooking vessel

3.. Corn steeping conveyor

4.. Corn washing conveyor

5. Corn Discharge conveyor

6. Soaking Tank system

7. Corn Exit Conveyor

8. Platform

9. Discharge conveyor

Fried Corn Nuts Equipment

1. Vibratory de-watering conveyor

2. Feeder with Air knife

3. Continuous Fryer with external heat exchanger

4. Cooking oil storage tank

5. Cooling Conveyor

6. Seasoning Machine

Corn Nuts Fryer Main Body Standard Equipped:

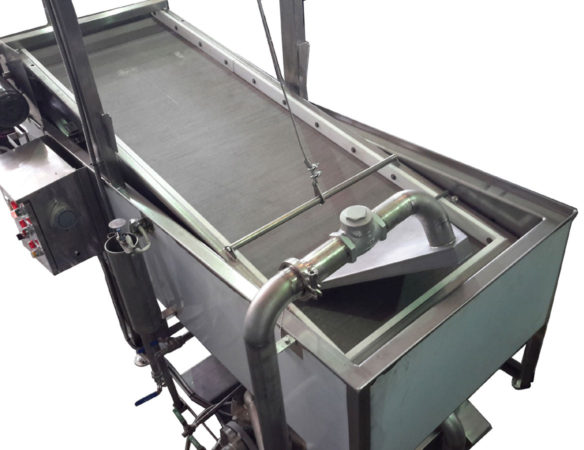

- Single Stainless net conveyor

- Frequency converter (Taiwan made)

- Self-locking motorized screw jacks raise the hood

- Drum Coarse Oil Filtration

- Clean-in-place spray nozzles in the hood

- Oil level control is maintained automatically.

- PLC touch control panel

- All stainless 304 # main body and piping (piping within the 3 meters, except transmitted parts not stainless steel)

- Net conveyor spec. 1.6 * 1.6 * 6 * 12

- ALLAN’s unique continuous fryer designs help you produce the products of the best quality.

Features,

- ALLAN’s unique continuous fryer designs help you produce the products of the best quality.

Features: - Continuous oil circulation through the fryer, filter and heat exchanger provides the precise control of temperature and quick adjustment while changing the amount of the products.

- Oil inlet maintains stable oil flow to clear the product in feeding area without

- creating back eddies or undercurrents.

- Fryer metering paddles and a submerge conveyor help to control cooking time for

- consistent and uniform products.

- Superior oil quality, Low oil volume and rapid oil circulation assure the freshness of the product with a long shelf life. Oil level is maintained automatically.

- Easy cleaning: Clean-in-place (CIP) spray nozzles in the hood and exhaust stack

- help clean all oil circulating areas. Circulating cleaning system circulates the cleaning water and Sodium bicarbonate following the same path as cooking oil, thoroughly cleans and sanitizes all areas.

- Self-locking motorized screw jacks raise the hood, paddles, and submerge conveyor, giving the complete access to the frying bed.

- Friendly design for easy operate and maintenance.

- Pressure switch to check frying oil pressure inside the piping.

- Emergency STOP button on both sides for safety operation.

- AII motors are provided with overload protector for safety operation.

- PLC touch panel. Use water proof control box to protect electric components.

- Oil can be screened continuously, food won’t be stained.

- Automatic control to quantity of oil, together with spare of oil supplying tank.

- Conveyor can be rise and fall for easily clean.

- Special design to oil soot collecting, filthy oil will not seep through back.

- Oil temperature and flow speed can be certainly controlled.

- Frying time can be adjustment.

- Indirect heated, quality of food is stable, so food shelf-life can be extended.

- Fuel can be chosen as: diesel, heavy oil or gas.

- Automatic fire lighting, keeps detect system the oil pressure, and secure safety of operators.

- Whole machine is made by stainless steel.

- External heat exchanger energy up to 3,500,000 KCAL per hour.

Main Export Market

Europe ,Middle East ,North America ,Oceania ,South America, Africa ,Asia