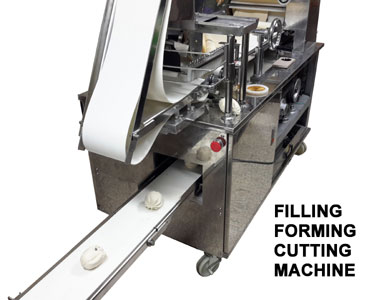

Through the special designed mechanisms, rolling, sheeting, wrapping extrudeding, folding and forming to produce max. 32 layers dough balls. After pressing, the layer parathas are finished. Equip a filling & forming mechanism, the dough balls can wrap various stuffing automatically to produce different taste of stuffed parathas and pastries, such as curry pastries, barbecued pork pastries, bean paste Pastries, etc

Capacity: 3000-3500 pcs per hour

FEATURES,

1. Rolling dough sheet.

2. Place dough into the hopper. Special designed reverses rollers to sheet dough into a thin dough belt. Save time, space and does not destroy the texture of dough.

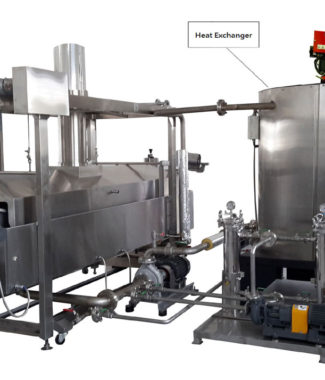

3. The margarine is extruded on the dough belt. To wrap the margarine inside the dough sheet. The margarine will not leak out to destroy the layers of pastry.

4. Expanding folding mechanism swings the dough belt with margarine inside onto the delivering conveyor to increase the layers of pastry.

5. Rolling mechanism rolls up the dough belt into a dough bar by means of the speed difference between the special rollers and conveyor. It can equip an extra stuffing extruder to roll up a stuffed dough cylinder.

6. The plain or stuffed dough bar goes through the wrapping mechanism to be formed into dough balls. The both ends are closed to keep from the leak of stuffing and keep the layers.

7. The press mechanism presses the finished products onto the conveyor. The products also can be stacked at a setting quantity, then delivered out by conveyor.

8. After resting, place the dough balls between the top and bottom films, then through a sensor, they will be delivered to the pressing location to be pressed into finished products.